Abstract

GMCC has successfully developed an innovative 5000F ultracapacitor with higher energy density (>10 Wh/kg) in 60138 standard size, which can offer high power density, almost instant charging and discharging, high reliability, extreme temperature tolerance, and a service life of over 1,000,000 charge-discharge cycles simultaneously. The GMCC 5000F cell can greatly enhance the inertia support and the ability of primary frequency modulation for the power grid, and improve the performance of equipment in the network. Meanwhile, the GMCC 5000F cell can satisfy auxiliary low temperature cold start, power support, energy recovery, wire-controlled low voltage power supply for automotive and other power applications.

Introduction

Ultracapacitors, as a highly reliable power source that provides high current in a short period of time, have attracted increasing attention nowadays. With the more and more global electrification, immense efforts have been made to improve energy and power density, quality, safety, and reduce the cost of energy storage devices. Ultracapacitors are increasingly accepted as energy storage systems enabling automotive applications such as advanced driving assistance (ADAS), innovative suspension and anti-roll bar systems, and advanced emergency braking system(AEBS), etc. In the near future, in the face of large-scale energy grid connection of clean energy such as photovoltaic and wind power, it is expected that ultracapacitors will usher in accelerated development in new power systems, such as power grid frequency modulation.

Fig. 1 GMCC 2.7V 5000F EDLC cell

5000F Ultracapacitor Technology

At present, the maximum capacitance of the cell in the supercapacitor industry is only 3000F, and because the specific surface area of activated carbon in the positive and negative electrodes is far from being effectively utilized, the current effective utilization rate is only about 10%. If the energy density bottleneck and limitations of ultracapacitors are broken, some fundamental innovations and adjustments must be made from the material structure, solid-liquid interface, and electrochemical system.

GMCC has carried out multi-dimensional comprehensive technical optimization, involving molecular/ionic scale, material micro and nano structure scale, material micro solid-liquid interface scale, material particle scale, high-capacitance electrochemical system development, cell structure design, etc. Firstly, the pore structure and surface characteristics of carbon materials have been deeply analyzed and optimized, and the carbon material is specically designed with an interpenetrating hierarchical porous structure (micropores, mesopores, and macropores are mutually unobstructed). Secondly, key indicators such as ion size, ion activity, solvation effect, viscosity of the electrolyte have been comprehensively considered. Based on the matching study of material/electrolyte solid-liquid interface, the specific surface area of activated carbon is fully utilized to the maximum extent, and the amount and ability of surface adsorbed charge are greatly improved. Thirdly, the special separator is made of composite fiber material, and has the characteristics of high strength, high porosity and high liquid absorption ability. Subsequently the non-polluting dry electrode process is adopted to greatly improve the compaction density of the electrode. Meanwhile, it also makes the cell have better vibration resistance and life performance, and the adhesive fibrosis process adheres to and winds on the surface of the material particles to form a “cage” structure, which facilitates the adsorption of the electrolyte and the transmission of ions. Finally GMCC adopts the all-tab, all-laser welding technology process, and the obtained cell is a metallurgical hard-connected structure with low ohmic contact resistance and excellent vibration resistance, which meets the requirements of the automotive grade AECQ200 standard.

| ELECTRICAL SPECIFICATIONS | |

| Type | C60W-2R7-5000 |

| Rated Voltage VR |

2.7 V |

| Surge Voltage VS1 |

2.85 V |

| Rated Capacitance C 2 |

5000 F |

| Capacitance Tolerance 3 |

-0%/+20% |

| ESR2 | ≤0.25 mΩ |

| Leakage Current IL 4 |

<9 mA |

| Self-discharge Rate 5 |

<20% |

| Max Constant Current IMCC(ΔT = 15°C)6 | 136 A |

| Max Current IMax7 | 3.0 kA |

| Short Current IS8 | 10.8 kA |

| Stored Energy E 9 | 5.1 Wh |

| Energy Density Ed 10 | 9.9 Wh/kg |

| Usable Power Density Pd11 | 6.8 kW/kg |

| Matched Impedance Power PdMax 12 |

14.2 kW/kg |

Tab. 1 GMCC 2.7V 5000F EDLC cell basic electrical specification

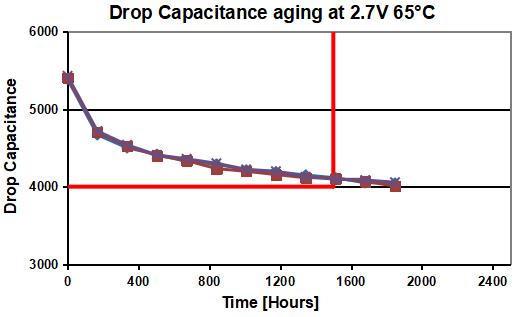

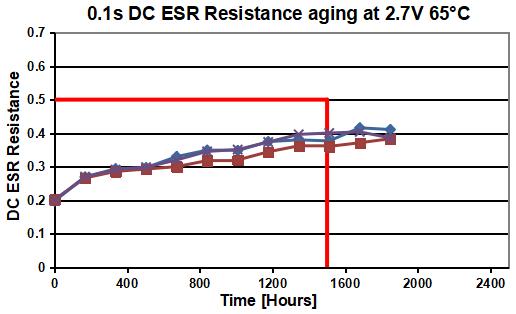

In order to specify an ultracapacitor with a rated voltage, the cell must meet certain conditions. A standard has been established in the industry over the course of last years. When kept at the maximum operating temperature (65oC for most ultracapacitors) and rated voltage, the cell must achieve a defined lifetime while remaining within the defined end of life criteria. The lifetime is set at 1500 hours for most ultracapacitor manufacturers and the end of life criteria are less than 20% nominal capacitance loss and a maximum increase of 100% of the specified ESR value. Fig.2 shows that GMCC 5000F ultracapacitor can meet these conditions.

Fig. 2 Capacitance(left curve) and ESR (right curve) evolution of GMCC 5000F ultracapacitor kept at a temperature of 65 oC and voltage of 2.7V.

The Future

We believe that target‐oriented, intensive R&D activities will enable us to further improve the overall cell performance, especially the cell voltage. Based on current laboratory results, we expect the next cell voltage level to occur in the foreseeable future. This will enable us to increase the energy and power density of GMCC ultracapacitors and thus keep pace with the trend towards ever smaller and more powerful energy storage solutions.

Post time: Oct-09-2023